E-Mail-Format Feeler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

News

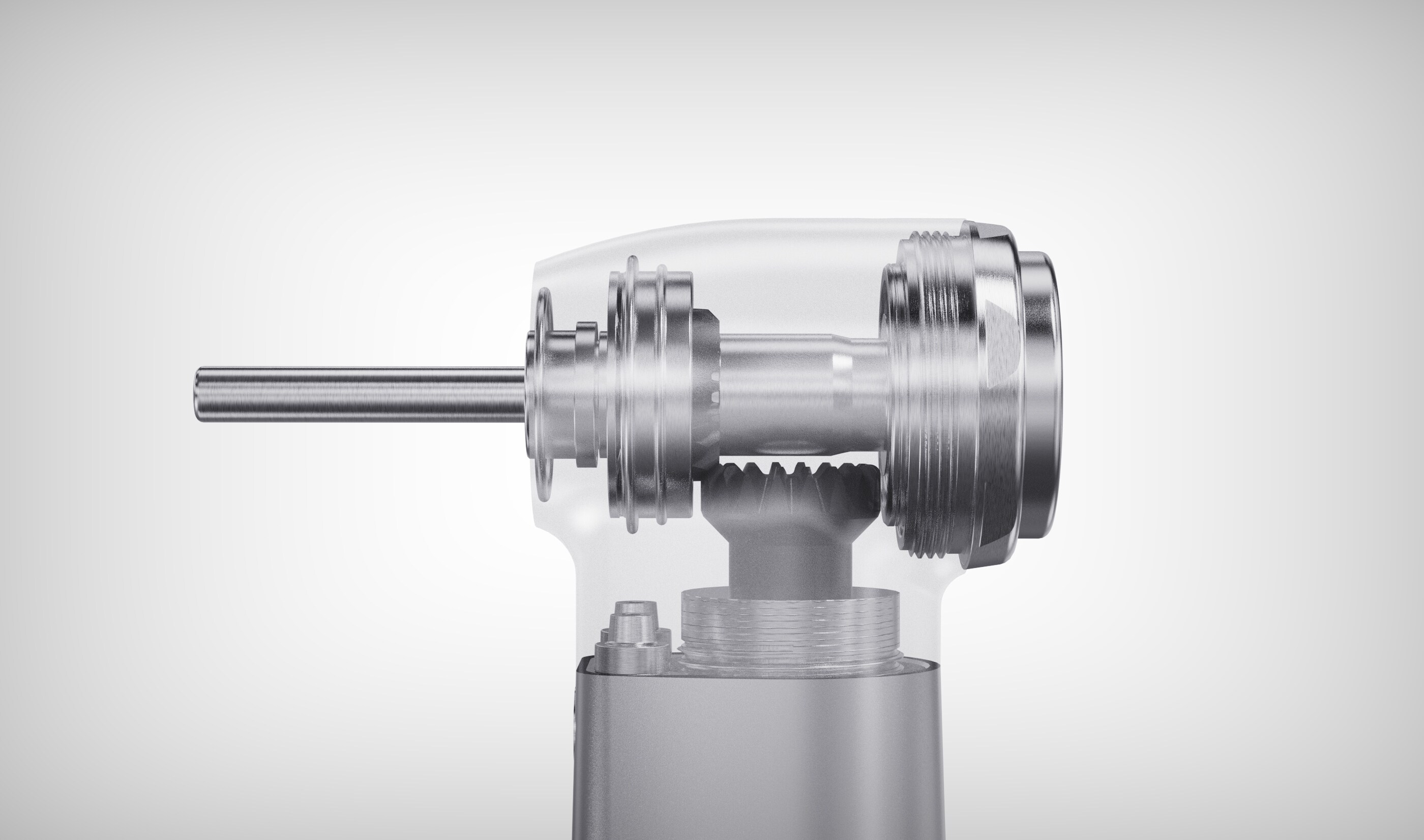

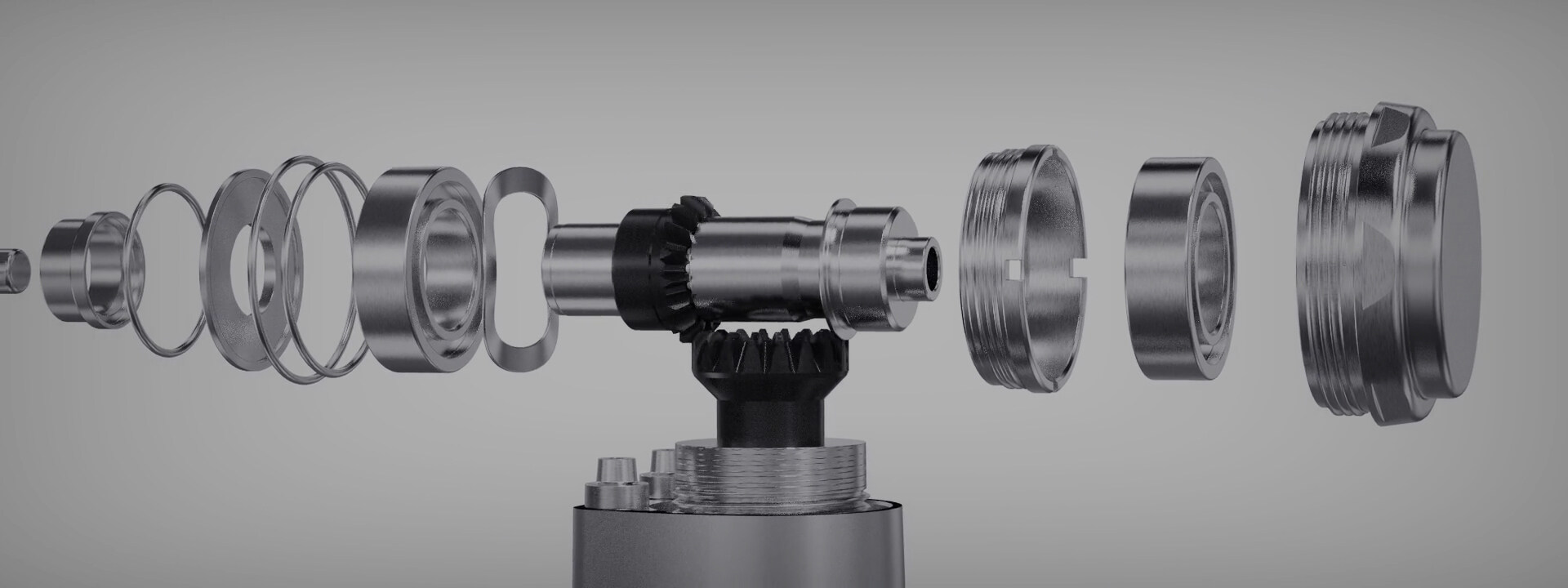

How to Maintain and Sterilize Low Speed Dental Handpieces

To keep the devices operating at full capacity and safe for your patients, maintaining and sterilizing low speed dental handpieces is a must. The following are the basic steps:

How to maintain and sterilize low speed dental handpieces

The first step to maintaining and sterilizing your low-speed dental handpieces is to surface clean the product. To do this, take a damp cloth that may be disposed of and wipe the unit down. It is important to ensure that you remove all bioburden that is present on the handpiece.

If the damp cloth does not successfully remove it all, you may use a brush and a small amount of mild detergent. You should never place your handpiece completely in water, cleaner, or any type of disinfectant solution.

Lubrication is an essential task when it comes to your dental handpieces. It is best to lubricate the motor of your device after every 5 autoclaves. Simply obtain a pen-shaped oiler and place up to 3 drops of the oil into the air tube of the drive mechanism.

When debris accumulates on your low-speed handpiece, you should ensure that you clean the threads of the device. In most instances, this should be done approximately once each month. To thoroughly clean the threads, you should use isopropyl alcohol and a paper towel.

It is common for expelled fluids and other types of debris to end up on the exterior surface of your handpiece. To remove these substances, use a dry towel to clean the exterior surface of the tool.

Each of the low-speed dental handpieces that you use in your practice includes the manufacturer’s instructions on bagging and sterilization. You should refer to these instructions at this point in the maintenance of your product. During the sterilization process, it is imperative to ensure that you allow your dental handpiece to dry, completely, before use. You should avoid in the act of lubricating the device once it has been sterilized and dried.